Partnering to advance cold glue application and sensor technology

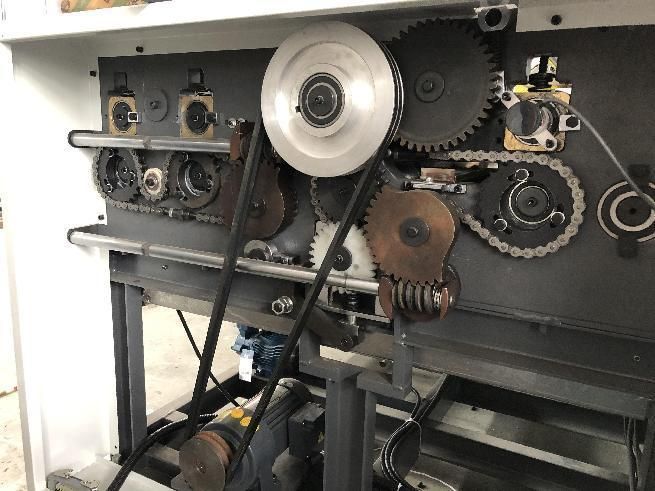

As a producer of high-end folding cartons, WestRock in Düren is the ideal partner for Baumer hhs when field-testing new equipment. The new PX 1000 cold glue application head and new GDX 1000 cold glue monitoring sensor recently were put through the last stages of development at WestRock before market introduction. This powerful combination of the PX 1000 and GDX 1000 for gluing and monitoring sets new standards, reduces quality costs in folding carton production and makes it easier for the plant to produce packaging of the highest quality. High Speed Lock Bottom Folder Gluer

“We always have the latest, market-leading equipment from Baumer hhs for adhesive application and quality control on our machines so that we can explore its advantages for our customers at an early stage. In turn, we also influence its development with the high demands we place on the performance, user-friendliness and reliability of our production systems,” says Giuliano Terracciano, head of Finishing and the Gluing Department. WestRock-owned multi packaging solutions Düren GmbH is happy to act as a sparring partner for Baumer hhs.

The three-shift plant in Düren specializes in premium paper and board packaging for confectionery products. “Top quality is just barely good enough for our customers. Baumer hhs can put its innovations to the acid test on our machines under very demanding conditions, using both relatively simple cartons run at high speed, as well as more complex packaging. Our two companies have been working together very closely for many years on advanced projects,” explains plant manager Dirk Matzke.

“Baumer hhs asked us in autumn if we would be interested in testing a new cold glue head, developed specifically to also process complex packaging at high speeds, in one of our folder-gluers. The new cold glue PX 1000 application head and GDX 1000 monitoring sensor were installed at the plant in late 2020. In the lab, the new head had achieved outstanding results in a number of categories, including start-up behaviour, precision application and flexible response to fluctuating adhesive viscosities. Baumer hhs now wanted to see if it could verify these advantages under demanding production conditions over an extended period of time,” says Terracciano in retrospect.

After just a few trials runs in the folder-gluer, machine operators were thrilled with the new equipment because it significantly facilitated their work. “The PX 1000 doesn’t need to be cleaned as often. Production interruptions due to cleaning are down considerably as a result, which benefits packaging production productivity. What’s more, the new head applies adhesive more precisely and in smaller dimensions than we have ever experienced before. It exploits this advantage when packaging products with small flaps and very high machine speeds. The new head makes it easier than ever for us to avoid inside gluing and ensure the functionality of our packaging products,” says Terracciano, emphasizing important changes associated with the PX 1000.

For example, in the production of telescope-type boxes with side seam gluing for chocolates, the PX 1000 applies the glue lines exactly from the defined start to endpoints. “Generally speaking, the new head once again significantly increases the reliability of the adhesive application and therefore of the overall production process. Our machine operators can be sure the glue is applied right where it belongs – and only there,” Terracciano adds.

Another advantage of the new head is how it facilitates the work of machine operators – The PX 1000 works smoothly and reliably even when it cycles relatively infrequently, as is the case in the production of lock bottom boxes.

“During the trial runs, we suggested that Baumer hhs make several optimizations, which they implemented perfectly,” says Terracciano, illustrating again how working in close partnership to improve gluing equipment in folding carton production results in various synergies for both Baumer and WestRock.

The new GDX 1000 cold glue monitoring sensor prototype was installed in the folder-gluer alongside the PX 1000. Its high resolution and innovative measuring principle based on the latest electronics guarantees even more reliable control of the gluing process right up to the highest machine speeds – which is a plus for demanding folding cartons applications in particular.

“The GDX 1000 greatly simplifies the monitoring of glue-free areas,” says Terracciano. Mac