For full functionality of this site it is necessary to enable JavaScript. Here are the instructions how to enable JavaScript in your web browser.

Save to read list Published by Sol Klappholz, Assistant Editor World Cement, Tuesday, 19 September 2023 15:28 Empty Ton Bags

Gaziantep-based big bag producer Prof Sentetik manufactures big bags with recycled polypropylene. To meet the high standards for heavy-duty tape fabric, Starlinger’s eqoCLEAN melt filter at the tape extrusion line ensures the purity of the melt.

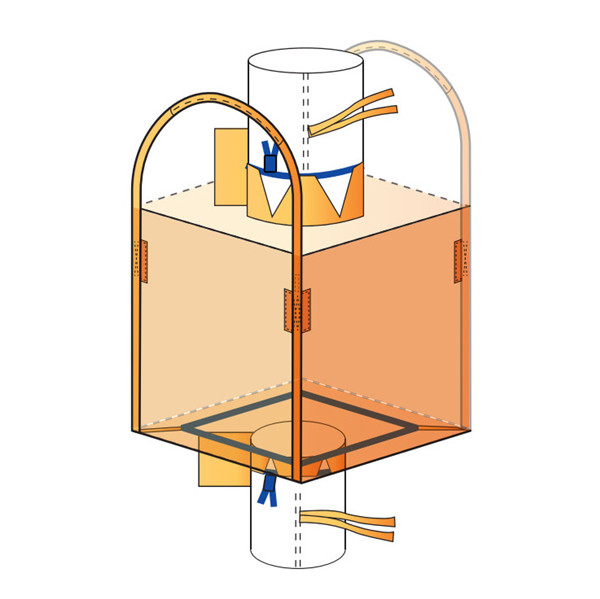

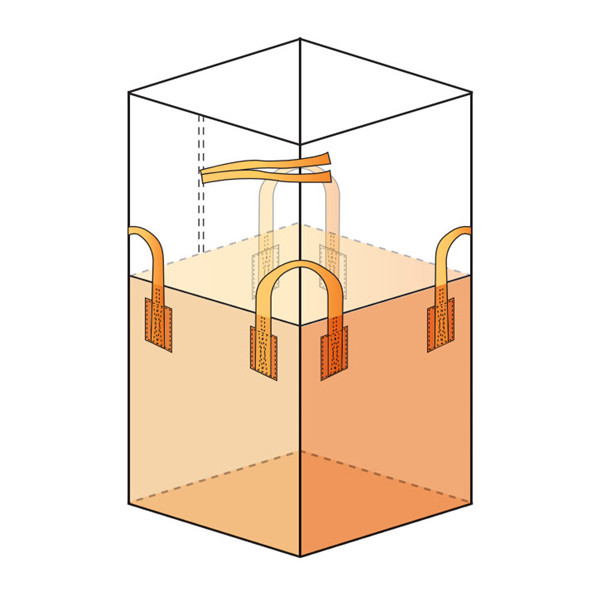

Big bags, also called FIBCs, are omnipresent in logistics as a lightweight and economical type of packaging for free-flowing bulk goods. Made predominantly from polypropylene (PP), they show a CO2 balance per 1,000 litres of transported goods that is far below that of rigid containers such as drums or octabins. Turkish big bag producer Prof Sentetik is making them even more sustainable by adding post-industrial and post-consumer PP waste in the production of various types of big bags. The company has recently installed Starlinger equipment for woven PP bag and big bag production, including a Starlinger PP tape production line equipped with the new eqoCLEAN filter system for processing recycled granulate. With this new tape extrusion line, Prof Sentetik produces PP tapes for FIBC fabric with recycled polypropylene (rPP) that meet all the specifications required for heavy-duty packaging applications.

“Plastic waste is a valuable resource, and instead of depositing it in landfills or incinerating it, it should be used in the best possible way”, said Fahri Sengül, General Manager of Prof Sentetik. “For us, Starlinger’s holistic approach to packaging production is very helpful. Being a supplier of both production machinery for woven plastic packaging and plastics recycling equipment, they understand the product cycle of plastic packaging from the beginning right to the end. They know how to produce high-quality recycled plastics, and their woven packaging production equipment is designed for processing virgin as well as recycled input materials, even if they stem from post-consumer plastic waste.”

“Companies like Prof Sentetik are real pioneers on the packaging market”, said Harald Neumüller, Sales Director at Starlinger. “With their technical competence and future-oriented mindset they drive the market toward a sustainable circular economy. A closed packaging loop for big bags works well if the big bags are made for recycling – meaning that they are designed and produced with recycling in mind and thus can be recycled easily at the end of their use phase. The better the recyclate quality, the higher can be the recycled content in the newly produced big bag”, explained Neumüller. To be able to use a high share of recycled content in big bags, it is important to follow the rules for Design for Recycling (DfR) which are summarised in a guideline established by EFIBCA, the European Flexible Intermediate Bulk Container Association. The guideline focuses mainly on the mono-material principle by reducing foreign materials in sewing yarns, belts, additives, inks, etc. used for big bag production.

Prof Sentetik currently processes in-house production waste and additionally buys recycled PP granulate, produced also from post-consumer plastic packaging waste. “As big bags have to meet special safety standards, the quality of the recycled material plays an important role in tape production”, confirmed Fahri Sengül. “The Starlinger tape extrusion line with the eqoCLEAN filter module ensures that the tapes we produce meet the specifications regarding tensile strength and elongation required for big bags in heavy-duty applications.”

The extrusion of heavy-duty PP tapes with recycled content, especially from recycled post-consumer plastic waste (PCR waste), requires adequate melt filtration. The share of rPP materials which can be processed depends on various factors, for example from which waste stream the post-consumer waste comes from, or how the waste was handled during collection and storage. Fine filtration already before tape extrusion, i.e. during the recycling process, is crucial. Solid contaminants which can occur in PCR materials, as well as foreign polymer particles in the melt – e.g. from polyester sewing yarn – compromise tape quality and cause problems in the tape production process.

The eqoCLEAN filter module developed by Starlinger takes into account all the requirements for producing high-quality PP tapes with post-consumer recycled PP. It consists of a SPB single-piston power-backflush filter, a melt pump, and a second filter unit, called HS 2.0 filter. The SPB filter has one piston and four cavities for filter screens and can be used for processing polyolefins such as PP or PE. During the hydraulic power-backflush procedure the line operates at full production speed without interruption of the production process. The regular automatic high-pressure backflushing procedure cleans the filter screens throroughly, increasing their lifetime and reducing machine downtime significantly. The melt pump in combination with the additional HS 2.0 filter, which is positioned directly before the extrusion die, ensure stable production and high operational reliability of the line. It also enables the processing of high shares of CaCO3 and post-consumer recycled PP of 50 % and more.

Following the tape production process, the tapes are wound onto bobbins and turned into big bag fabric on Starlinger’s heavy-duty circular looms. In the last step, the woven fabric is converted to big bags. Properties such as tensile strength, weight and safety factor of Prof Sentetik’s big bags with rPP content meet all required safety standards and are continuously tested using standard testing procedures and certified equipment.

“We are very satisfied with how things are going”, said Fahri Sengül. “We even aim to increase the recycled content in our big bags to 50% and more. Also, we are considering to install our own Starlinger plastics recycling line – it can be the first step towards establishing a closed packaging loop for big bags here in Türkiye with our local big bag users. We have to think about our environment and take care of nature. We all – consumers, manufacturers and equipment suppliers – must work together to stop the destruction of the environment.”

Read the article online at: https://www.worldcement.com/africa-middle-east/19092023/recycled-big-bags-made-in-trkiye-with-starlinger-technology/

Join World Cement in Lisbon, 10 – 13 March 2024, for our first in-person conference and exhibition: EnviroTech.

This exclusive knowledge and networking event will bring together cement producers, industry leaders, technical experts, analysts, and other stakeholders to discuss the latest technologies, processes, and policies being deployed at the forefront of the cement industry’s efforts to reduce its environmental footprint.

Get your advance tickets NOW »

Sven Demmig and Sunny Schoone, Innomotics, a Siemens company, elaborate on how solutions in automation, electrification and digitilisation can help to decarbonise the cement industry.

Embed article link: (copy the HTML code below):

This content is available to registered readers of our magazine only. Please sign in or register for free.

Register for free » Get started now for absolutely FREE, no credit card required.

Already a member? Sign in here

Ready to revolutionise the cement industry?

Join World Cement in Lisbon, 10 – 13 March 2024, for our first in-person conference and exhibition:

This exclusive knowledge and networking event will bring together cement producers, industry leaders, technical experts, analysts, and other stakeholders to discuss the latest technologies, processes, and policies being deployed at the forefront of the cement industry’s efforts to reduce its environmental footprint.

Get your advance tickets NOW

Polypropylene Sacks Copyright © 2023 Palladian Publications Ltd. All rights reserved | Tel: +44 (0)1252 718 999 | Email: enquiries@worldcement.com