WMH have recently developed a side drive spiral conveyor system for use in a bakery environment.

Working closely with belt manufacturer, Intralox, WMH designers designed a twin spiral unit to give around 300 metres of conveyor length within a small factory footprint. The length of conveyor can be used for buffering of product or can be used as a holding facility to allow product to be rested for proving or ambient cooling whilst maintaining the benefits of an in-line production system. Frame Support Components

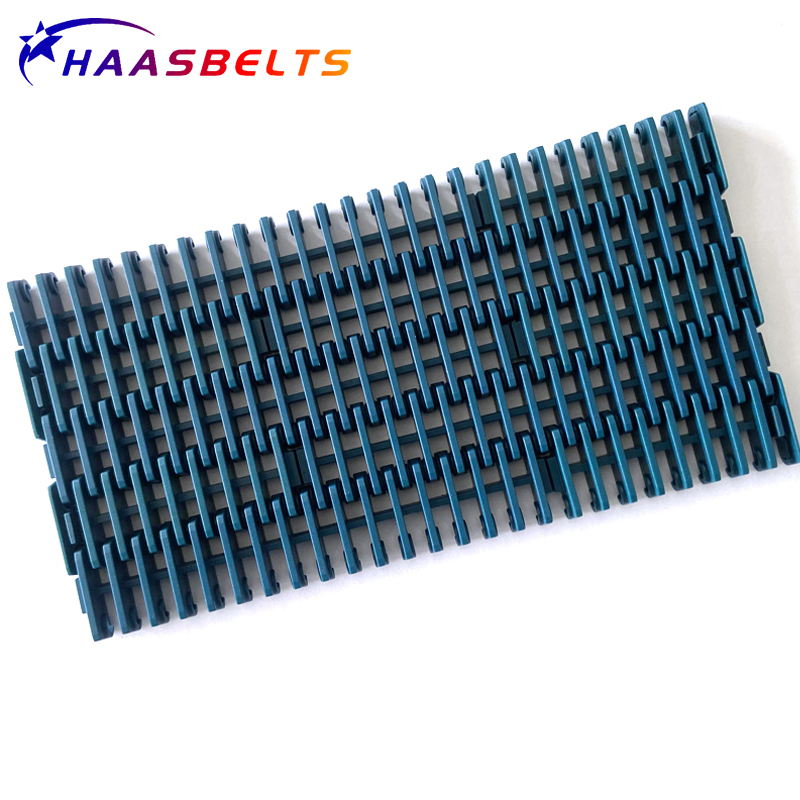

The spiral is fitted with Intralox’s side drive modular plastic belt that offers all the flexibility and hygiene benefits of their other modular belts with the addition of the side drive features which enables the conveyor belt to be driven from the side rather than the end. This drive arrangement eliminates the need for a long return belt path and spreads tension along the length of the belt. Driving the belt on the outside edge also makes access for cleaning and maintenance simple and reduces the moving parts of the machine to a minimum.

The first unit built has twin stacks of conveyor providing low level infeed and low-level outfeed for inline product proving, however the design could easily be configured to offer single stack configuration for elevating, de-elevating or reversible for buffing in case of a fault on the line.

As with all WMH conveyors, the spiral conveyor has been designed with hygiene at the core of the machine, using all stainless-steel construction with no open crevices that can act as debris and bug traps. The machine has been designed to be used in a wash-down environment and can be treated as other modular plastic conveyors within the factory.

“We are really pleased with the way this new design has gone together and look forward to being able to offer similar solutions in the future,” said a spokesman for WMH.

For more information about WMH and their range of bespoke product handling and conveying solutions please visit www.wmh-uk-ltd.com or call 01579 383788

A message from the Editor: Thank you for reading this story on our news site - please take a moment to read this important message: As you know, our aim is to bring you, the reader, an editorially led news site and magazine but journalism costs money and we rely on advertising, print and digital revenues to help to support them. With the Covid-19 pandemic having a major impact on our industry as a whole, the advertising revenues we normally receive, which helps us cover the cost of our journalists and this website, have been drastically affected. As such we need your help. If you can support our news sites/magazines with either a small donation of even £1, or a subscription to our magazine, which costs just £31.50 per year, (inc p&P and mailed direct to your door) your generosity will help us weather the storm and continue in our quest to deliver quality journalism. As a subscriber, you will have unlimited access to our web site and magazine. You'll also be offered VIP invitations to our events, preferential rates to all our awards and get access to exclusive newsletters and content. Just click here to subscribe and in the meantime may I wish you the very best.

The voice of the industry With over 60,000 readers throughout the UK and Europe, Food & Drink International is the most comprehensive medium for your company. No other magazine can guarantee such high profile coverage

Contact us: fdi@blmgroup.co.uk

© Food & Drink International - Part of the Business Link Magazine Group

By continuing to use the site, you agree to the use of cookies. more information Accept

Square Plastic End Caps The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.